Proposed Title :

Low Power and Low Cost Thermal Energy Harvesting Power Supply with an Internal Start up Circuit with regulator for Pacemakers

Proposed System:

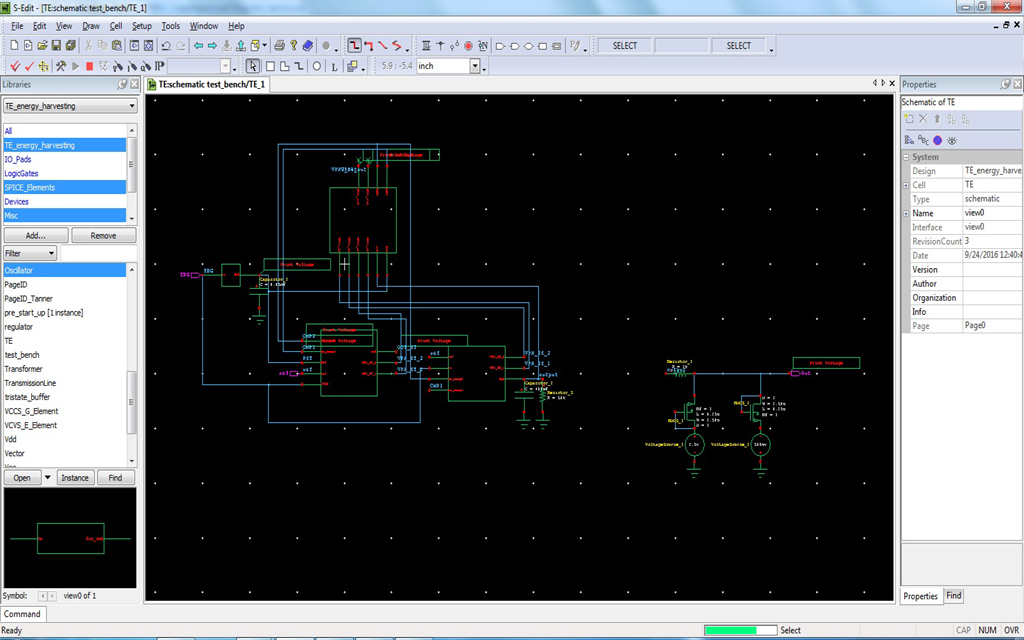

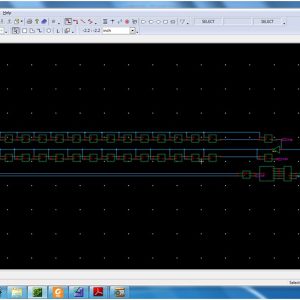

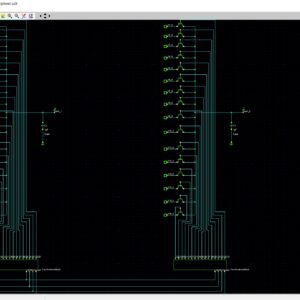

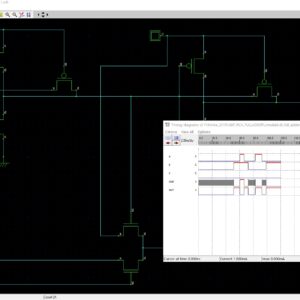

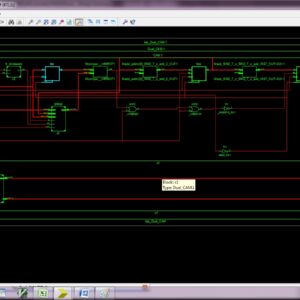

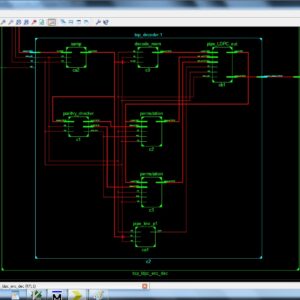

- In proposed system design is TE energy harvesting system with regulator.

- Design this architecture at 130nm level.

Software implementation:

- TANNER

Reviews

There are no reviews yet.